News

Difference between Thin Gauge & Heavy Gauge Thermoforming

Thin-gauge thermoforming is primarily the manufacture of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food, medical, and general retail industries.

Sheet thickness less than 1.5 mm (0.060 inches) is usually delivered to the thermoforming machine from rolls or from a sheet extruder. Thin-gauge roll-fed or inline extruded thermoforming applications are used primarily to create rigid or semi-rigid disposable packaging.

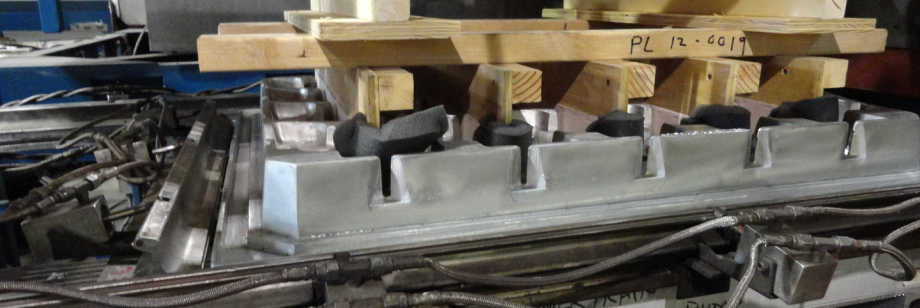

Thick-gauge thermoforming includes making parts as diverse as plastic pallets, dunnage trays, automotive components, sports and recreation products, and food industry packaging.

Sheet thicknesses greater than 3 mm (0.120 inches) is usually delivered to the forming machine by hand or by an auto-feed method, in which pieces are already cut to final dimensions.

What is Thermoforming?

Thermoforming is a manufacturing process in which a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold using air pressure or vacuum, and trimmed to create a usable product. The sheet, or “film” when referring to thinner gauges and certain material types, is heated in an oven to a temperature that allows it to be stretched or put into or onto a mold and cooled for a specific time to a finished shape.